Items can be supplied separately

Presentation ILS-270E

(PDF)

Presentation ILS-250E

(PDF)

ELECTRIC MOBILE DRILLING RIG 250 TON LOAD CAPACITY ILS-250E

ADVANTAGES

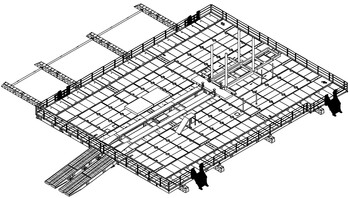

The drilling facility design enables derrick drawworks unit motion while derrick and drillfloor base are up (given drill stem setback) between boreholes at a distance of 200 m by means of platform with propulsion mechanism consisting of sections whose overall dimensions allow mud board transportation along by general purpose roads by means of universal vehicles.

Universality

Capability for both cluster and single-well drilling, and for side-tracking.

Pumps

Electrically-driven drill pumps capability for gradual buildup of pressure up to 350 atm, and for reaching flow rate of 60 L/s low mud pulse amplitudes.

Transportation

Reduction in time and costs for carriage of transportable assemblies of the drilling facility modules.

Software

The drilling facility control system software allows on-line in-operation troubleshooting.

Faster

Reduction in erection time during rig-up/rig-down; the erection time for modules corresponds to the untrucking time plus time for modules piping by means of QDC and electric cables by means of quick-detachable connections.

Protect

Protective lockouts system implemented in the drilling facility control system minimizes potential for emergencies due to ground equipment failure, and ensures protection from personnel misbehavior, and consequently cuts down on the process emergencies and accidents occurrence risk in respect of HSE.

STRUCTURE

| Parameter name, characteristics | Value |

|---|---|

| Permissible hook load in accordance with GOST 16293-89, kN (tf) | 2500 (250) |

| Maximum test load on the hook, kN (tf) | 3060 (312) |

| Nominal drilling depth according to GOST 16293-89, m | 4000 |

| Power supply of mobile drilling rig (MDR) from the industrial network, with the possibility of power supply from autonomous power supply sources of DGP | 6 kV, 50 Hz |

| Drilling rig component configuration | Block-modular; self-propelled MDR |

| Weight of the largest unit during transportation (except for the derrick drawworks unit semi-trailer) | at most 40 t |

| Drilling line system | 5х6 |

| Drilling line diameter, mm | 32 |

| Stand height, m | 18,5-21; 25 (without TDS) |

| Nominal pipe diameter, mm | 89, 102, 114, 121, 127, 146, 168, 178, 203, 245, 324 |

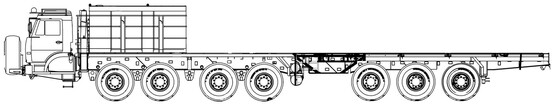

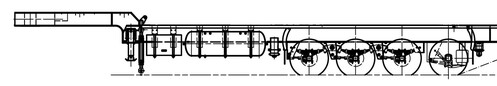

Self-propelled chassis 14x14

Semi-trailer

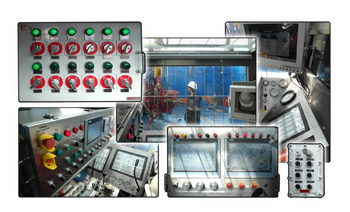

The following is implemented through the driller's cabin:

- the possibility of sound notification and voice guidance in case of exceeding the specified boundary parameters (main and secondary);

- shutdown of the system, controller unit and electric drive of the drawworks brake arm (including emergency).

- automatic transition to manual control when interacting with the brake arm.

- complete blackout of the system by a signal from an external source

- a gas analyzer, fire alarm, etc.

The automated control system of the drilling rig provides:

- automatic maintenance of the mechanical drilling speed;

- automatic bit feed depending on the pressure on the bit;

- automatic bit feed depending on the pressure drop;

- automatic bit feed depending on the moment by the tool;

- automatic system for maintaining the set speed of hoisting operations;

- automatic stabilization of the torque when drilling with rotation;

- automatic bringing the load to the bottom in the controlled-angle drilling mode by monitoring the position of the main shaft of the TDA and oscillation (rotation) of the drilling rig;

- automatic determination of the optimal drilling mode

| Parameter name, characteristics | Value |

|---|---|

| DW type | Single drum with work line damper |

| Carrying capacity, t | 250 |

| Power at the DW drum, kW | 1000 |

| Tractive effort, kN | 280 |

| Drive type | Electric, VFD |

| DW drive power, kW | 1000 |

| thread on a drum for a line 32 mm | Lebus |

| Main brake | Dynamic braking by DW electric motor |

| Parking brake and emergency brake | Disc brake |

| Hook lifting speed, m/s | 0 – 1,5 |

| Type of DW emergency drive | Electric, VFD |

| Emergency drive motor power, kW | 45 |

| Hoisting speed of hook block with a load of 250 tf, m/min (m/s) | 0,8 (0,013) |

| Parameter name, characteristics | Value |

|---|---|

| Rotary base type | Double parallelogram |

| Height to rotary beam, m | 6 |

| Standback capacity (drill pipes with DP lock 89/114 mm), stands/meters | 215/4000 |

| Working place, m | 8х6,2 |

| Rotor type | Р-700 |

| Wellslot orifice diameter, mm | 700 |

| Nominal diameter of pipes, gripped by pneumatic power slips ПКР and ПКРО, mm | 89, 102, 114, 121, 127, 146, 168, 178, 203, 245, 324 |

| Rotor drive | Individual from 690V electric motor with VFD |

| Electric motor power, kW | 400 |

| Rotation frequency, rpm | 0-250 |

| Maximum torque on the rotor table (at a rotor speed of 100 rpm), kN*m | 40 |

| Maximum short-term torque on the rotor table, kN*m | 60 |

Specifications

- Using of drillpipes and stands (heavy-duty drillpipes, steel drillpipes, casing pipes)

- Built-in spinner for make-up

- Built-in travel system Installation of racks height along

- Automation of operations

- Remote control

- Use of casing pipes: up to 20“

- Sizes of used DP and stands: 4 ¾ "- 9 ½"

- Max. spinner torque: 4,000 Nm

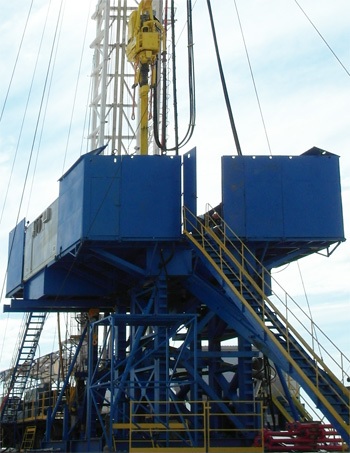

Designed to move drilling equipment without dismantling during well construction by the cluster method.

| Parameter name, characteristics | Value |

|---|---|

| Permissible load on the hook of the drilling rig, at most, kN (tf) | 2451 (250) |

| Acceptable load on the SEFDR when moving, tf | 500 |

| Acceptable load on SEFDR during drilling operations, tf | 750 |

| Weight of the drilling equipment to be placed, at most, t | 736 |

| Height to the bottom of the mobile platform, mm | 900 |

| Height at the top of the mobile platform, mm | 1400 |

| Dimensions of the mobile platform, mm | 20000х30000х500 |

| Location of drilling rig wind guy attachment points | within the mobile platform |

| Location of drill pipes when moving | in the racks of the stabbing board of the derrick-man |

| Method of moving | sliding on support beams |

| The speed of movement of the equipment of the drilling rig between wells, m/h | up to 4 |

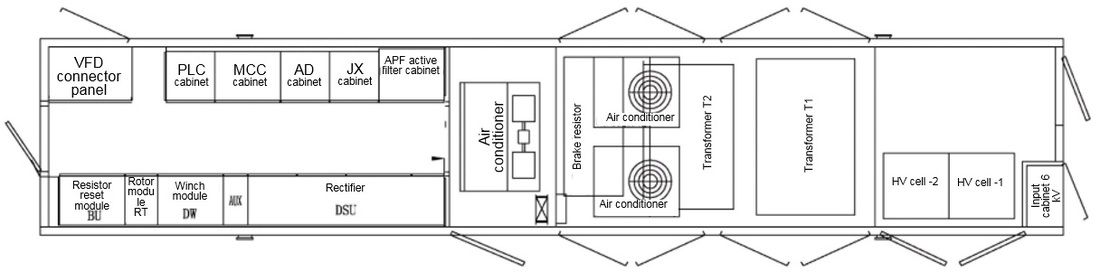

Designed to control the operation of the DW and rotor.

The module includes:

- Two high-voltage single-end service assembled chambers (КСО)

- Input cabinet 6 kV

- Input cabinet 0.69 / 0.6 / 0.4 kV

- Transformer 6 kV / 2x0.69 kV

- Transformer 6 kV / 0.6 kV / 0.4 kV

- Frequency converter of rotor and DW

- VFD/LVCD control system cabinet

- Electricity distribution cabinet No. 1

- Electricity distribution cabinet No. 2

- DW emergency drive cabinet

- APF active filter cabinet

- Braking resistors

The drilling rig control system has:

- Electronic control units of the system (driller's console and the workplace of the foreman, supervisor) with display of the set drilling parameters with reference to time.

The electronic control unit of the system includes software that allows you to perform:

- collection, storage and processing of information;

- data storage in non-volatile memory with the ability to view the archives of the operating parameters of the system in the form of graphs (locally and remotely), as well as view the log of events, accidents and actions of the operator/driller;

- remote access to the System (with limited management functions);

- uploading reports in *.xls,*.pdf formats, for a user-selected period of time

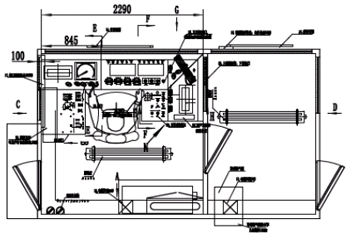

Fitted in a mobile building of automobile dimensions (container type 40 ft HQ):

| Model | BENTEC TD-250-C | SLC DQ40BQ-JH |

|---|---|---|

| Drive type | Electric variable speed drive | Electric variable speed drive |

| Max. load | 250 t | 250 t |

| Voltage | 575VAC/50HZ | 600VAC/50HZ |

| Current load (max) | 610A | 698A |

| Nominal motor power | 500 kW / 672 h.p. | 375 kW / 503 h.p. |

| Speed range | 0 - 200 rpm | 0 - 180 rpm |

| Working torque | 47,75 kNm | 40 kNm |

| Max. uncoupling torque | 60 kNm | 60 kNm |

| Backup tong range | 68,6 - 191 mm | 86 - 206 mm |

| Wellslot orifice diameter | 76 mm | 76 mm |

| Wellslot orifice PN | 50 MPa | 35 MPa |

| Ambient operating temperature | -45... +55°С | -45... +55°С |

| Weight of main components | 10,8 t | 9,84 t |

| Overall dimensions of the main components | 5534х1401х1595 mm | 4830х1360х1220 mm |

The system is designed to clean the drilling mud from cuttings, maintain the specified mud parameters, make and store a new mud.

The mobile drilling rig uses two separate modules of the cleaning system, which are interconnected by a communication quick-release box.

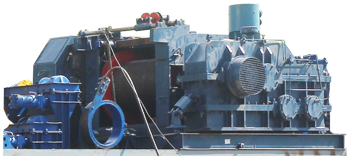

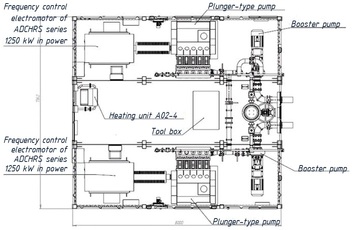

Consists of 3 modules.

In transport dimensions LxWxH: 8000x2450x3000 mm.

Weight of the main 2 modules is 22 t each.

Intermediate module weight - 8 t.

Installation time for the pumping unit is 1.5 hours.

Possibility to pressurize the high pressure line without the involvement of special equipment.

Head and rate characteristics of plunger pumps QWS-2500 with electric motor 1250kW

| Motor rpm | 60 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1350 | 1500 | 1650 | 1800 | 1950 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pupm rpm | 9,4 | 47,2 | 70,8 | 94,4 | 118,1 | 141,7 | 165,3 | 188,9 | 212,5 | 236,1 | 259,7 | 283,3 | 306,9 |

| Plunger Ф 4 "(101.6 mm) | |||||||||||||

| Flow rate, l/s | 1,3 | 6,5 | 9,7 | 13,0 | 16,2 | 19,4 | 22,7 | 25,9 | 29,2 | 32,4 | 35,7 | 38,9 | 42,1 |

| Pressure, MPa | 50,1 | 50,1 | 50,1 | 50,1 | 50,1 | 50,0 | 47,6 | 41,6 | 37,0 | 33,3 | 30,3 | 27,8 | 25,6 |

| Plunger Ф 5 "(127 mm) | |||||||||||||

| Flow rate, l/s | 2,0 | 10,1 | 15,2 | 20,3 | 25,3 | 30,4 | 35,5 | 40,5 | 45,6 | 50,6 | 55,7 | 60,8 | 65,8 |

| Pressure, MPa | 35,1 | 35,1 | 35,1 | 35,1 | 35,1 | 32,0 | 30,5 | 27,7 | 23,7 | 21,3 | 19,4 | 17,8 | 16,5 |

Head and rate characteristics of plunger pumps QWS-2500 with electric motor 1600kW

| Motor rpm | 60 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1350 | 1500 | 1650 | 1800 | 1950 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pupm rpm | 9,4 | 47,2 | 70,8 | 94,4 | 118,1 | 141,7 | 165,3 | 188,9 | 212,5 | 236,1 | 259,7 | 283,3 | 306,9 |

| Plunger Ф 5 "(127 mm) | |||||||||||||

| Flow rate, l/s | 2,0 | 10,1 | 15,2 | 20,3 | 25,3 | 30,4 | 35,5 | 40,5 | 45,6 | 50,6 | 55,7 | 60,8 | 65,8 |

| Pressure, MPa | 50,1 | 50,1 | 50,1 | 50,1 | 48,1 | 45,0 | 42,6 | 36,6 | 32,0 | 28,3 | 25,3 | 21,8 | 20,6 |

Rated: 6 kV.

Number voltageof connected electric motors: 2 pcs.

Maximum power of the electric motor: 1600 kW.

The equipment is housed in a 40-ft HQ container.

| Regulation and control of the | |

|---|---|

| Mud pump and aux. equipment: - Supercharger pump - Rod reflux pump - Grease pump | Electric motor and its systems: - Electric heating bundles - Ventilation |

| Visualization | |

|---|---|

| on the driller and assistant driller panels: - Pressure/flow rate - Current moves - Alarm/ready - Fault warnings - Alarm/warning codes | at the SGU Terminal: - MPCS status and mode - HV circuit status - State of the MPCS equipment - Event log and archive |

| Control and protection of the |

|---|

| Mud pump and aux. equipment: - Mud pressure. Protection against mechanical destruction of the manifold - Mud flow rate - Thermal protection of the electric motor of auxiliary pumps - Air pressure in the airclutch |

| Electric motor and its systems: - Temperature of the stator, bearings - Thermal protection of fans |

| Drilling processes: - Automatic regulation of the mud feed volume depending on the pressure - Pressure build-up protection |

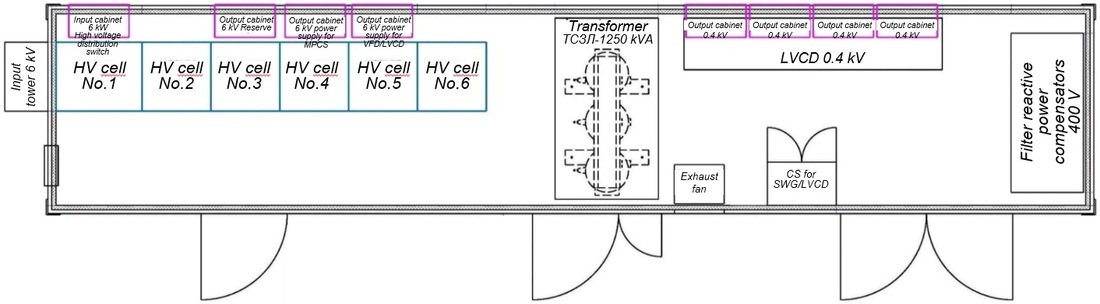

The switchgear of low-voltage complete devices of the mobile drilling rig (SWG/LVCD) is designed to receive and distribute the electric power of the rig and compensate for reactive power.

| Parameter name | Value |

|---|---|

| Number of high voltage cells | 6 |

| Rated voltage, kV | 6 |

| Rated current of main circuits КСО, А | 1000 |

| Power input 6 kV to SWG/LVCD, 2 options | - from the input tower; - cable input. |

| Number of low-voltage power distribution cabinets in SWG/LVCD | 5 |

| Rated voltage, kV | 0,4 |

| Rated current of main circuits КСО, А | 2000 |

Designed for equipment heating, washing, cleaning and other operations with low pressure steam (up to 0.8 MPa)

Features:

- startup time - 30 sec

- electricity costs are 2.5 times lower than existing electrical analogs

- Rostekhnadzor rules do not apply

| Parameter name | Value |

|---|---|

| Unit productivity in terms of steam, kg/hour | 500 to 4000 |

| Overall dimensions, by performance | Container 20-40 feet |

| Ambient temperature, °С | -45 to +45 |

| Unit weight, by productivity, kg | 4500 to 12000 kg |

| Maximum steam pressure at the outlet, MPa | 0,8 |

| Supply voltage, V | 380 +/- 5% |

| Power consumption, kW | 320 |

| Steam capacity control | in stages 200-300 kg/hour |

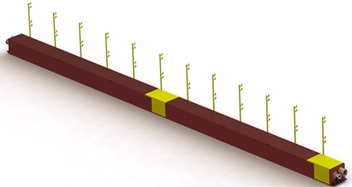

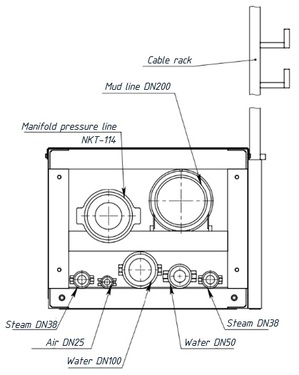

Designed for quick installation, dismantling of process communications sections. It is a thermally insulated body in which various pipelines are mounted, connected by quick-disconnect couplings. Cable racks are provided for mounting overhead electrical power and control cables.

| Name | Value |

|---|---|

| Overall dimensions of the CQRB section | At most (LxWxH/stand) mm, 10500 x 830 x 650/1950 |

| Stand for cable line | At least 6 pcs per 1 CQRB section |

| Weight of one CQRB section | At most 1900 kg |

| Name | Q-ty | Material | P working - MPa | Coupling |

|---|---|---|---|---|

| High pressure manifold НКТ-114 | 1 | Steel | 50 | Quick disconnect coupling -4" |

| Mud channel DN-225 | 1 | PE | 1 | BAUER 8" (steel) |

| Water pipeline DN-80 | 1 | Steel | 1 | Camlock |

| Water pipeline DN-50 | 1 | Steel | 1,6 | Camlock |

| Steam pipeline DN-38 | 2 | Steel | 0,8 | Camlock |

| Air pipeline DN-24 | 1 | Steel | 1,6 | Camlock |

FEEDBACK

Буровая компания "Евразия", Когалымский филиал

Управление буровыми насосами.

В настоящее время на объектах Когалымского филиала ООО "Буровая компания "Евразия" эксплуатируется 19 комплексов управления буровыми насосами производства ООО "Л-Старт".

С.А. Сокол

Начальник службы АСУТП

Буровая компания Сибирь

Насосный блок с ЧРП

Гарантии ООО "Л-Старт" поставки оборудования в кратчайшие сроки позволили нашей компании получить объемы производства ... В первые же месяцы работы после внедрения оборудования буровой бригадой был поставлен рекорд скорости проходки.

С.В. Курбацкий

Директор

Новоуренгойское управление буровых работ

Комплекс управления буровыми насосами

Используя собственные наработки, компания Л-Старт качественно и в срок разработала, изготовила комплекс КУБН-1.1250 и выполнила его поставку в ООО "НУБР" в комплекте с асинхронными электродвигателями на замену синхронных.

В.В. Подшибякин

Генеральный директор

Буровая компания "Евразия", Пермский филиал

Управление буровыми насосами

Оборудование ООО "Л-Старт" (УПП и ВПЧ) успешно эксплуатировались в жестких условиях и показали стабильно высокие результаты. За время работы оборудование зарекомендовало себя с лучшей стороны, сбоев в работе и отказов за все время эксплуатации не было. Рекомендую оборудование производства ООО "Л-Старт" к эксплуатации.

Ф.Ф. Минибаев

Главный энергетик

Уренгой бурение (Газпром бурение)

Комплекс управления буровыми насосами

ООО "Л-Старт" выполнило поставку Комплексов управления буровыми насосами собственной разработки в комплекте с электродвигателями и эластичными муфтами...

В.В. Курбацкий

Главный энергетик

Мегионское управление буровых работ

Комплекс управления буровыми насосами

Наличие высоковольтного частотно-регулируемого привода в системе управления буровыми насосами позволило производить регулировку подачи буровых насосов с заданной точностью.

Ю.И. Бузинов

Генеральный директор

Буровая компания "Евразия", Усинский филиал

Управление буровыми насосами

Оборудование ООО "Л-Старт" показало высокую эффективность работы. Претензий и нареканий к работе оборудования со стороны эксплуатирующего персонала Усинского филиала ООО "Буровая компания "Евразия" отсутствуют.

А.Н. Никулин

Главный энергетик

PARTNERS

CONTACTS

LOCATION

125212, Moscow, Vyborgskaya st., 16, Bldg. 4, office 502

BUSINESS HOUR

Monday-Friday

9:00-18:00 Msk

TELEPHONE

+7 (495) 935-73-21

info@L-Start.ru

Leave your contact details

We will call you back!

LLC "L-Start"

+7 (495) 935-73-21